LABORATORIES & PHARMACEUTICALS

HORIZONTAL CYLINDRICAL AUTOCLAVE STERILIZER

SAFTEY FEATURES

- Self-locking safety door which cannot be opened while chamber is under pressure.

- Hydraulically Tested to 2.5 times the designed working pressure.

- Individual Safety Valves for Chamber/Jacket/ & Steam Generators.

- Automation controlled pressure in chamber/jacket & steam generator.

- Heat resistant Food Grade Silicone door gasket for 100% Sealing.

- Pressure switches on all models for power saving & energy efficient operation.

- Low water protection system to protect the heating coils.

- Vacuum breaker valve for pressure equalization after vacuum creation.

- Resin Bonded Rock wool insulation covered with Mirror Finish S.S.304 sheet to minimize heat loss & surface temperature of the equipment.

- All necessary Relays, Contactors, MCB’s & Overload Relays are provided in the control panel for maximum protection against electrical surges.

- Optional UPS Power back up system provided for Automation system to protect the critical electrical components like HMI, PLC’s & Modules.

Chamber & Jacket - The material used for chamber is of heavy duty 316 L /304 L grade stainless steel Sheets for both GMP Model & Standard Model.

Doors - The doors are constructed of heavy duty 304 L /316 L grade stainless steel Solid Plate, both single and double door models are available with Flush Mounting panel on the Sterile Side Door.

Piping - The pipes and fittings are made up of S.S 304/316 Quality

.Operating Valves – The Branded Manual/Electric/Pneumatic Valves are made up of Heavy-duty S.S 304 Quality for all models.

Mounting & Control Panel – The Autoclave is mounted on a Tabular Stand along with control panel made up of S.S 304 Quality for GMP Model & M.S quality powder coated for Standard Model.

Loading Tray – The Autoclave would be provided with a S.S 304 / S.S 316 Quality perforated tray at the bottom of the chamber to place the Materials, Dressing Drums Etc. This tray is easily removable & cleanable.

Inbuilt Steam Generator - The Autoclave is provided with an Inbuilt Electrically fired Steam Generator mode up of S.S 304 / S.S 316 Quality to generate its own clean & pure steam to be used in the chamber during the sterilization cycle. It comes with all Safety features like Low Water protection system, Safety valve, pressure switch etc.

Direct Steam Heated - If Inbuilt Steam generator is not opted then customer can provide the clean & pure steam from their own Centralized Boiler which will be connected to the Autoclave via PRV valve, Strainers & Moisture Traps.

Fully Automatic Touch Screen HMI & PLC operating system.

This system is highly sought after in almost all the industries who requires latest technology automation system in their Autoclaves.

Cycle phases which can be operated Automatically includes Pulsing, Pre-Vacuum, Heating, Sterilization Hold, Slow Exhaust, Fast Exhaust, Post- Vacuum Drying, Etc.

This control system is based on state-of the art technology programmed inhouse to ensure high precision & highly reliable cycle operation. The PLC control unit ensures a fully automatic operation throughout the entire cycle.

The control system is easy to use and programmable to run Standard Sterilization cycle programs like Gravity Cycle, Pulsing Cycle, Pre-Vacuum & Post-Vacuum Cycle, Liquid Media Cycle, Dry Load Cycle, Flash Cycle & 2 Optional Test programs like Vacuum Leak Test & Bowie Dick Test.

Optional 21 CFR Part 11 Compliance software shall be provided along with this operating system to remotely operate & monitor the Sterilization cycle via software installed on a remote Computer/PC which is connected to the Automation control panel through LAN/Ethernet Cable. The same software can be used to save the sterilization cycle data & also take a hard copy printout of it through any printers attached to the same network

Optional Sterilization Cycle Online/Offline printing facility is also available with this operating mode. An Epson Branded Dot Matrix printer is provided along with this system which is connected to the Automation Panel. The printer generator a hard copy printout of the Sterilization cycle which includes information concerning the cycle operation such as the Company Name, Manufacturer’s name, date, time, Batch number, Set Parameters, Temperature, Pressure & other cycle phase information. An Optional Strip Chart recorder system is also available for the same.

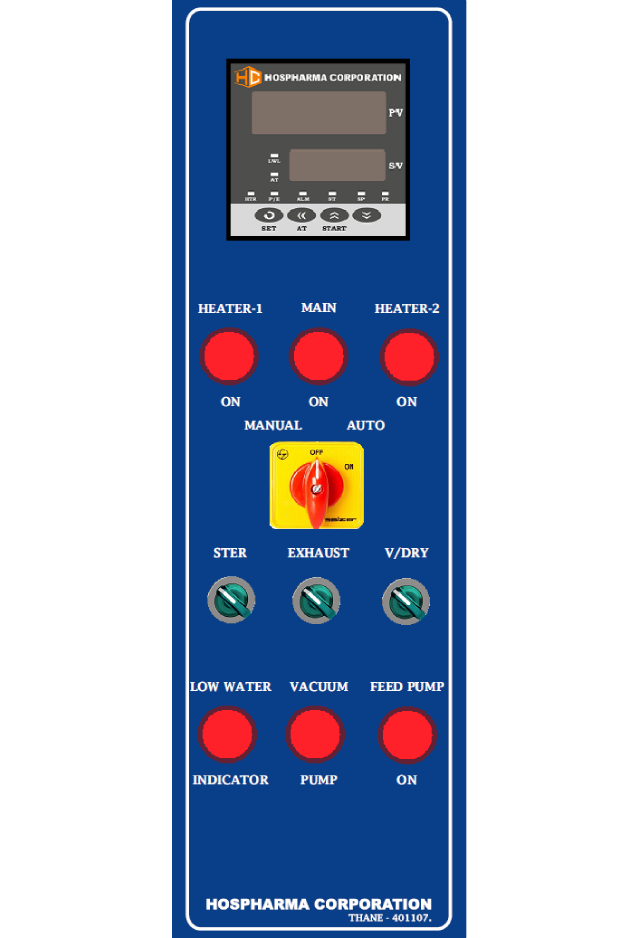

Semi-Automatic operating system via Microprocessor/PLC based Digital Temp Indicator & controller.

This system is developed specifically to reduce user involvement during the cycle operating.

Cycle phases which can be operated Automatically includes Sterilization, Slow/Fast Exhaust & Optional Automatic Vacuum Drying.

This system is highly reliable & safe. The keyboard located on the front panel enables the operator to select a program, start and stop the cycle, and allows a trained technician to pre-set the main parameters using an access code. The control system is easy to use and programmable.

The User selects the Parameters like Temp, Hold Time & vacuum time which are easily settable. Once the user presses the start key, the cycle runs & controlled Automatically & its live data like temp, pressure & hold period etc is displayed on the LCD screen of the controller. At the end of the cycle, Buzzer sound notifies the user of the cycle completion.

Sterilization cycle data printing facility is available with this operating mode. An Epson Branded Dot Matrix printer is provided along with this system which is connected to the Control Panel of the Autoclave. The printer generator a hard copy printout of the Sterilization cycle which includes information concerning the cycle operation such as the date, time, Batch number, temperature, pressure & other cycle phase information. An Optional Strip Chart recorder system is also available for the same.

Manual operating system

Via Multiport Operating Valve to control the entire Sterilization cycle.

Cycle phases which can be operated includes Sterilization, Slow Exhaust, Fast Exhaust & Vacuum Drying.

This is a cost effective, simple, easy to operate & maintenance free operating system.

Outer Cabinet Enclosure - This Optional Outer Cabinet is opted for elegant & aesthetic look of the Autoclave Sterilizer. The Equipment is mounted on a tubular stand which would be fitted on S.S 304 /M.S Quality Frame & there would be S.S 304/M.S Quality Powder Coated cabinet Enclosure covering the whole machine with maintenance doors on the sides. The S.S Cabinet would be Mirror/Matt Finished as per the customer’s requirements.

Trolley & Carriage with Trays - This is an Optional Accessory provided with all the models to assist with the loading and unloading process. The Loading Carriage with adjustable trays are made up of S.S 316 / S.S 304 Quality & Transfer trolleys are made up of S.S 304 / M.S Quality Powder Coated with heavy duty castor wheels.

Vacuum Pump & Condenser - This is an additional accessory provided along with the Autoclave Sterilizer for Creating Full Vacuum of -760 mm of Hg in the chamber for mechanical air removal prior to sterilization and subsequently for post sterilization vacuum drying process. This system is required for Pre-Vacuum & Post Vacuum Cycles along with other test cycles. The Water ring Vacuum Pump is mounted near the Autoclave or on the Service Floor & is connected with S.S 304 Quality Steam to Water Condenser system which cools the steam and converts it into water before it goes in the vacuum pump. It protects the vacuum pump and enhances its working and noise reduction.

Automatic-Water Feeding System – The Autoclave is provided with an Automatic water feeding system to fill up the water in the inbuilt Steam generator automatically & stop the water flow once the Water level reaches the required mark. This is done through high quality sensors and Crompton Branded motor which can also fill the water in the Steam Generator with pressure in it as well as during running cycle. With this system, the user can operate the Autoclave continuously for long hours.

Air Compressor – This optional Accessory is provided along with the Equipment to provide pressurized compressed air to operate the Pneumatic Valves of the Autoclave in case the customer doesn’t have a centralized compressed air line available on site. The Compressors are available in many variants like Oil Free, Noise Free, Compact, Reciprocating, Etc.

PRV Line Assembly – This optional accessory is provided along with direct steam heated Autoclave Sterilizers where the steam is directly provided from the customer’s centralized Boiler. This system includes PRV Valve, Strainers, Moisture Traps & Pressure Gauge.

Hospharma Corporation also provides Onsite Validation Services for our Equipments. After the completion of the Installation process, the validation process begins where multiple 9/12/16 sensors would be placed at different location inside the chamber through the validation port and temperature mapping would be done for sterilization cycles to validate the equipment. All the Calibration Certificates & & Validation documents shall be provided along with Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ) & Design Qualification (DQ). Validation is performed with 16 channels Datalogger which is 21 CFR Part 11 Compliance. Document contains protocol procedures, Pass Criteria, F Zero / Fh Value, Lethality, Graphical Representation, Conclusion, Hot Point, Cold Point & Result. Validation Done As per HTM 2010 & EN285 Guidelines. We also provide consumables required during the Validation process like Ampoules, Chemical Indicators, Biological Indicators, Bowie Dick Test Kits, Sterilization Tape Etc.

TABLE SPECIFICATIONS

| MODEL | C-24 | C-36 | C-48 | C-45 | C-60 | C-72 | C-90 | C-108 | C-150 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Chamber Dim. MM | D | 400 MM | 400 MM | 400 MM | 500 MM | 500 MM | 600 MM | 750 MM | 900 MM | 1000 MM |

| L | 600 MM | 900 MM | 1200 MM | 900 MM | 1200 MM | 1200 MM | 1200 MM | 1200 MM | 1500 MM | |

| Chamber Vol. | Lit. | 75 | 100 | 150 | 180 | 225 | 340 | 500 | 750 | 1150 |

| Steam Generator | Lit. | 50 | 60 | 75 | 75 | 75 | 75 | 90 | 100 | 100 |

| Power (3 phase) | KW | 6 KW | 9 KW | 12 KW | 12 KW | 18 KW | 18 KW | 18 KW | 36 KW | 36 KW |

| WITH AUTOMATIC WATER FEEDING SYSTEM | ||||||||||

.png)

About Us

About Us