SPICE & HERBS INDUSTRIES

SPICE STEAM STERILIZER R & D MODEL

SAFE AND HEALTHY STEAM STERILIZATION OF SPICES & HERBS

- Spices and herbs bring a world of flavors, aromas and colors to our dining tables. Spices and herbs are sourced worldwide and they may be heavily contaminated from the soil where they were grown and harvested. If left untreated, these products can provide perfect conditions for continued growth of the microbes which can lead to spoilage and consumer health issues.

- The Spice sterilizer R & D model gives the user a template of parameters like Sterilization temp, Hold time, Drying time, etc to be used for bigger load in the bigger capacity models. Users can test few small batches (100 to 500 grams) of Various spices in this R. & D Model to obtain the exact parameters required to sterilize the bigger load. By this system the user has control over the process & avoid any losses to bigger batches which can occur by setting the incorrect parameters.

- It is a cyclic process comprising of pre-vacuum, steam injection & drying to the desired final moisture content. The cycle time is 50-60 minutes. It is effective in completely eradicating salmonella and E. Coli, Yeast & Mould, spore formers & other dangerous microorganisms. Reduction from 3 to 7 logs with Effective microorganism kill while causing the minimum harm to the organoleptic characteristics (flavor, color, texture or taste) of spices, herbs and nuts.

FEATURES

- The R & D Lab models are available in capacities ranging from 1 kg/batch to 10 kg/batch.

- This R & D Model is Highly recommended for obtaining sterilization parameters like Temp, Hold Time drying time for High Value Imported spices & Herbs.

- Powdered, Granular, Whole Spices/Herbs & Leafy products can be treated.

- Easy to Operate with inbuilt Steam generator & Full Vacuum Drying system based on Venturi technology to reduce the moisture percentage from the sterilized spices & herbs.

- All models are Fully Stainless Steel GMP manufactured.

- Small & Compact so that it can kept inside the Laboratory.

- Can be customized to make it table top or bench top model.

- Works on normal single-phase electrical connection available in Labs.

- Compact Hygienic design & high-quality finish.

- Automatically controlled with Minimal operator intervention.

- Operator only needs to select the right setpoints & operate few Valves.

- Inbuilt flexibility as mix of different products requiring similar treatment can be processed in one single batch

- Guaranteed Uniform Sterilization.

- Unique trays system design configurations to easily load & unload the products.

- Easy Cleaning & Quick changeover of products saving a lot of time.

- Plug & Play system which requires no Installation. Just connect the Utilities & Operate it.

- All Safety related to the pressure vessel like pressure switches, safety valves, provided with utmost importance.

Chamber & Jacket - The material used for chamber is of heavy duty 316 L grade stainless steel Sheets for GMP Model & Standard Models

Doors - The doors are constructed of heavy duty 316 L grade stainless steel Solid Plate.

Piping - The pipes and fittings are made up of S.S 316 Quality.

Operating Valves – The Branded Manual/Electric/Pneumatic Valves are made up of Heavy-duty S.S 304 Quality for all models

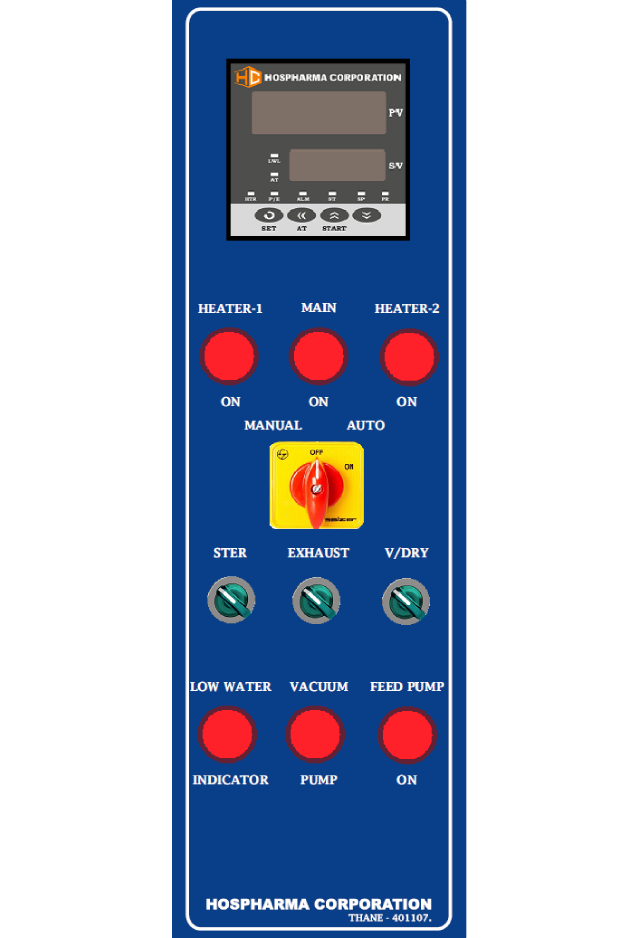

Mounting & Control Panel – The Sterilizer is mounted on a Tabular Stand along with control panel made up of S.S 304 Quality for all models

Trays – The S.S 316 QualityTrays are provided with all the models to assist with the loading and unloading process.

Inbuilt Steam Generator - The Sterilizer is provided with an Inbuilt Electrically fired Steam Generator mode up of S.S 316 Quality to generate its own clean & pure steam to be used in the chamber during the sterilization cycle. It comes with all Safety features like Low Water protection system, Safety valve, pressure switch etc.

Fully Automatic Operating System Via Microprocessor/Plc Based Digital Temp Indicator & Controller.

Cycle phases which can be operated Automatically includes Heating, Sterilization Hold & Exhaust, Pre & Post- Vacuum Drying process needs to be performed manually by operating few ON/OFF Valves. This manual operation is to make the equipment simpler, compact & maintenance free.

This control system is based on state-of the art technology programmed inhouse to ensure high precision & highly reliable cycle operation.

VENTURI SYSTEM - This Feature is provided along with the Sterilizer for Creating Full Vacuum of -760 mm of Hg in the chamber for mechanical air removal prior to sterilization and subsequently for post sterilization vacuum drying process to reduce the moisture percentage of the final sterile spices & Herbs. This system only needs compressed Air to create vacuum in the chamber & it does not have any moving parts. It is maintenance free & highly reliable & efficient

Air Compressor - This optional Accessory is provided along with the Equipment to provide pressurized compressed air to operate the Pneumatic Valves of the Sterilizer in case the customer doesn’t have a centralized compressed air line available on site. The Compressors are available in many variants like Oil Free, Noise Free, Compact, Reciprocating, Etc.

Hospharma Corporation also provides Onsite Validation Services for our Sterilizers. After the completion of the Installation process, the validation process begins where multiple 6/9 sensors would be placed at different location inside the chamber through the validation port and temperature mapping would be done for sterilization cycles to validate the equipment. All the Calibration Certificates & & Validation documents shall be provided along with Installation Qualification (IQ), Operational Qualification (OQ), Performance Qualification (PQ) & Design Qualification (DQ). Validation is performed with 16 channels Datalogger which is 21 CFR Part 11 Compliance. Document contains protocol procedures, Pass Criteria, F Zero / Fh Value, Lethality, Graphical Representation, Conclusion, Hot Point, Cold Point & Result. Validation Done As per HTM 2010 & EN285 Guidelines.

TABLE SPECIFICATIONS

| MODEL | STR-15 | STR-19 | STR-24 | |

|---|---|---|---|---|

| Chamber Dim. MM | D | 300 MM | 350 MM | 400 MM |

| L | 500 MM | 550 MM | 600 MM | |

| Chamber Vol. | Lit. | 35 Liters | 52 Liters | 75 Liters |

| Powder Holding Capacity | KG/Batch | 1.5 kg/Batch | 2 Kg/Batch | 4 Kg/Batch |

| No of Trays | 3 | 3 | 4 | |

| Power (3 phase) | KW | 3 KW | 3 KW | 6 KW |

.png)

About Us

About Us